WPC External Cladding

WPC cladding is indeed an innovative building material that offers a combination of the visual appeal of wood and the practical benefits of plastic. Here are some key points to further understand this material:

Composition: WPC cladding is typically composed of a mixture of wood fibers or flour, recycled plastic, and a binding agent or polymer. The specific ratios of these components can vary depending on the manufacturer and intended application.

Prices from $37/board

Dimension:

219mm wide x 26mm thickness x 2.9m long

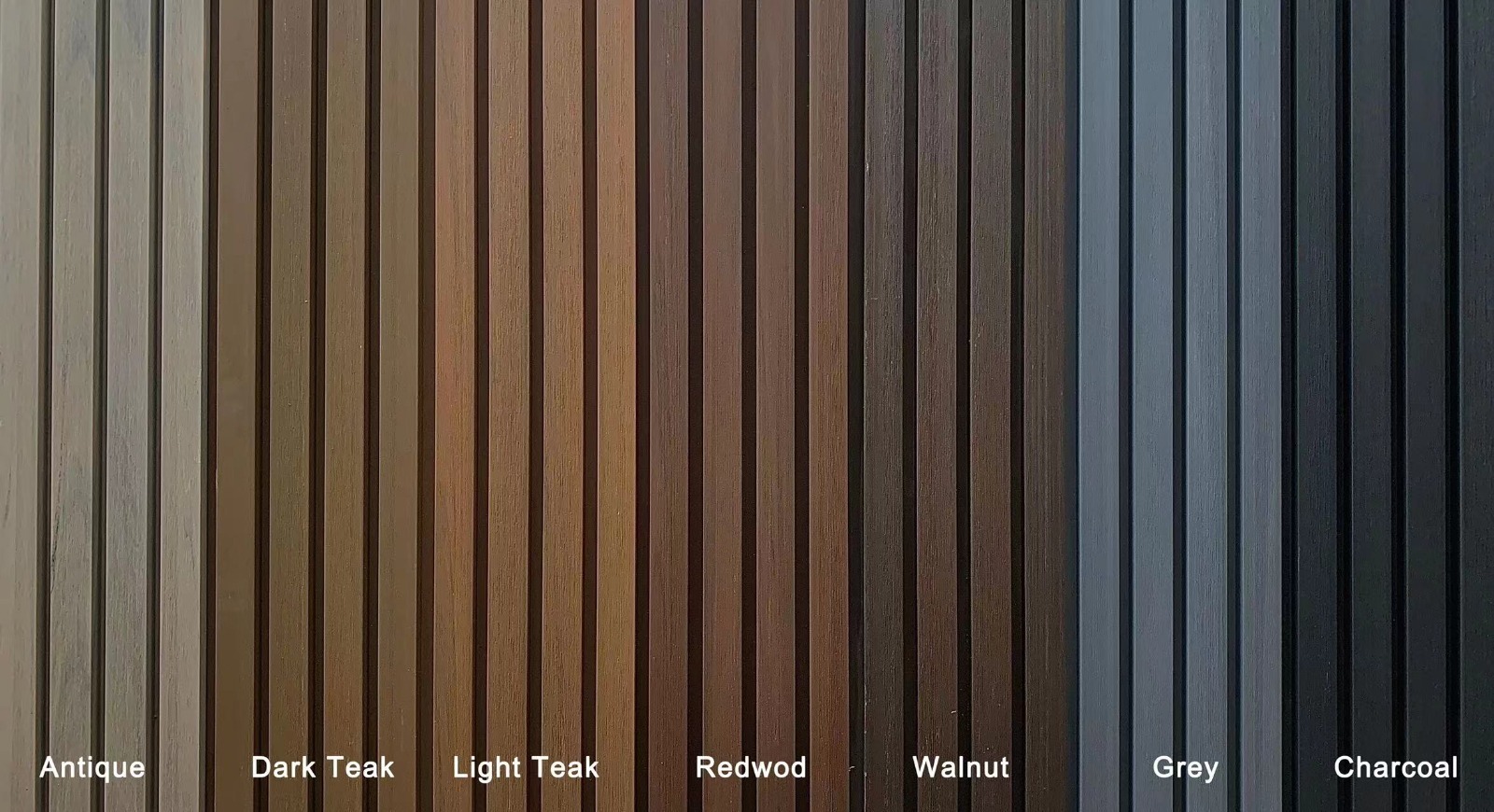

Color Range:

Charcoal,Redwood,Teak,Walnut,Antique,Grey

Features:

• Co-extrusion Brushed Surface

1. **Aesthetic Appeal and Durability**: WPC cladding offers the aesthetic

appeal of natural wood while maintaining the durability and low maintenance advantages of plastic. This combination makes it an attractive choice for building exteriors.

2. **Composition and Manufacturing**: WPC cladding is made from a blend of wood fibers, recycled plastic, and a binding agent. This mixture is molded into planks or tiles, which can be easily installed to cover the exterior surfaces of buildings.

3. **Weather Resistance and Longevity**: WPC cladding demonstrates excellent resistance to weathering, protecting it from issues like rot, mold, and insect damage. It’s also less prone to cracking or splitting compared to natural wood, resulting in a longer lifespan.

4. **Low Maintenance**: Due to its durability and resistance to environmental factors, WPC cladding requires minimal maintenance over time. This characteristic can save building owners both time and money in the long run.

5. **Customization**: WPC cladding is available in a wide variety of colors and finishes, including options that replicate wood grain, brushed metal, and stone effects. This versatility allows for the creation of customized and unique building exteriors.

6. **Environmental Friendliness**: One of the significant advantages of WPC cladding is its eco-friendly nature. It’s produced using recycled materials, helping to reduce the demand for new resources. Additionally, its manufacturing process typically involves fewer harmful chemicals compared to traditional building materials.

7. **Low Carbon Footprint and LEED Certification**: Because of its recycled content and reduced chemical usage, WPC cladding can contribute to a lower carbon footprint. This aligns with sustainability goals and could potentially lead to LEED certification, which recognizes environmentally responsible building practices.

Incorporating WPC cladding into construction projects showcases a commitment to combining aesthetics, durability, and environmental consciousness. Its various benefits make it a compelling choice for architects, builders, and property owners looking for a sustainable and visually appealing exterior solution.

1. Exterior Cladding: WPC cladding is particularly well-suited for exterior applications due to its durability and resistance to weather conditions. It can provide buildings with an attractive finish while also protecting them from the elements. Additionally, its low maintenance requirements make it a practical choice for long-term use.

2. Interior Cladding: Inside buildings, WPC cladding can be used for wall panels, ceiling tiles, and other decorative elements. Its ability to add warmth and texture to interior spaces makes it a versatile option for enhancing the aesthetics of indoor environments.

3. Fencing and Screening: The durability and weather resistance of WPC cladding make it an excellent choice for outdoor fencing and screening applications. It can create privacy screens, fencing panels, and decorative partitions that retain their appearance and functionality over time.

4. Landscaping: WPC cladding’s natural look and resistance to moisture and decay make it suitable for landscaping projects. Whether it’s used for decking, pergolas, or garden walls, WPC can help create outdoor spaces that are both visually appealing and long-lasting.

5. Signage: WPC’s durability and weather resistance also extend to signage applications. Using WPC for billboards, directional signs, and information boards ensures that the signage remains readable and intact, even when exposed to various weather conditions.

Measuring Guide:

219mm wide WPC Cladding

For example:

Step1: Please measure the wall height X wall width

The wall height is 2.8m long x 3m wide

Step 2: 3m(wall width) ÷ 0.219m(plank width)= 13.69= 14 panels

Materials Needed:

• Masking Tape

• Grab Adhesive or Double Sided Tape

• Black Screws and Electric Drill

• Tape Measure

• Circular Saw with New Fine-Tooth Blade

• Pencil

• Spirit Level

Preparation:

1. Measure each panel and the surface it will be attached to.

2. Apply masking tape to both sides of the panel to ensure a clean cut.

3. Mark the desired cut size on the masking tape.

Cutting the Panel:

1. Place the panel facedown for cutting.

2. Use a circular saw with a new fine-tooth blade to cut the panel to the accurate size across

the width.

3. While cutting, support both sides of the panel.

Installation Methods:

1. Place the panel facedown and choose either the adhesive or double-sided tape method.

Adhesive Method:

1. Apply a generous amount of grab adhesive to the back of the panel.

2. Carefully position the panel on the chosen surface.

3. Check if the panel is straight using a spirit level.

4. If you’re using screws, proceed to the next section.

5. Allow time for the adhesive to set.

Double-Sided Tape Method:

1. Apply double-sided tape evenly across the back of the panel.

2. Position the panel on the desired surface.

3. Ensure the panel is straight using a spirit level.

4. If screws are also being used, proceed to the next section.

Screw Method:

1. If you’re fixing the panel with screws, ensure you have your electric drill and black screws ready.

2. Place the panel against the surface.

3. Use the electric drill to drive screws through the panel and into the backing material.

4. Ensure the panel is securely fastened and straight.

These steps provide a clear and organized way to install panels using adhesive, double-sided tape,

or screws, depending on your preference. Remember to follow safety precautions while using tools and ensure that the panels are installed securely and straight for a professional finish

FIre Resistant

Our Interior profiles are fire-resistant, B1 fire rated.

Quick To Install

It's the perfect DIY project - even for

beginners.

Sustainable

Made from 100% recyclable and sustainable metarials.

- Low Maintenance

- Modern Design

- Natural - Looking

- Ready Stock

- Built to Last

- Factory Direct Price

- Eco Freindly

- Easy to Intsall

- 20 Years Warranty